"Big Foot 52"

or

Storage boxes etc.

(March till

April 2010)

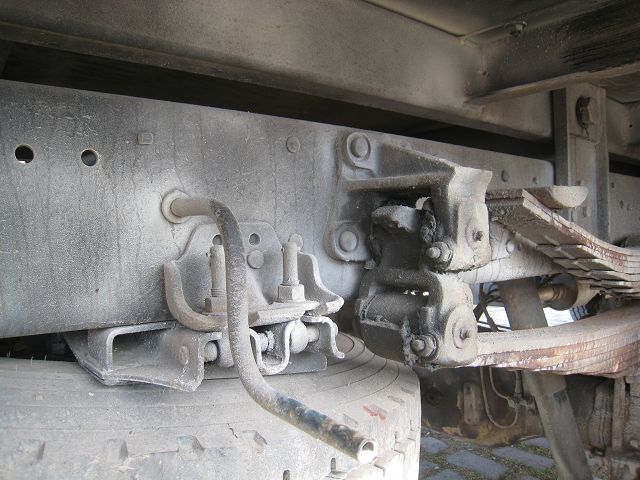

Finally I finished the last two storage

boxes! Some preparations were necessary. The box on the right side would have

got in conflict with the winch of the spare tire, so I cut off the end.

Then I welded a nut onto the stud and so I

can now lift or lower the spare tire with a ratchet.

The lever of the wastewater-valve would

have been in conflict with the box. So I exchanged it to an electric operated

one which has a mechanic override in case of problems.

The switch is located in the right storage

box but I installed an additional one in the dashboard (the left one), plus a

red indicator light if the valve is open. Because I anyhow had made a lot of

dirt I prepared in addition the switch for an additional diesel tank which I

will order shortly. The switch for the wastewater-valve saves me to go to the storage box when I had

driven to a dump-station and can open and close the valve from the driver seat.

The ground clearance due to the storage

boxes isn’t effected by any means. The one on the left side is mirrored but

besides that identical. They offer enough space for the 4 steel- and 4

aluminium-sand ladders, the rods for the awning, parts for the chairs, an

extendable ladder up to 3,8 m, the wheel chocks plus more.

The storage boxes were built around the

support frames to fix them directly to the ground plate of the cabin plus to

have some more space in the boxes. My first intention was to close the gaps but

my friend Orest recommended to add slide out rods. So now I have on both sides 2

40x40 mm stainless steel square tubes in which are square tubes as well out of

stainless steel of 35x35 mm. The bigger ones are 35 cm long, the inner ones are

75 cm long. So they can be pulled out up to nearly 40 cm. A wooden board fits in

and so I can use it to store various things on it. rods

The storage boxes I built in stainless

steel tubes which were cut in 30° and fitted with a mounting plate in front. In

front of the holes I built of PE sideways slide-locks to prevent water or dirt

to get in. The tubes are to put in the telescopic rods for the awning.

Without an additional spreader the awning

was not straight enough.

With the spreader out of stainless steel –

which can be split in the middle – the awning is now perfect.

A normal awning would have required from

my point of view supports right from the beginning of the cabin construction. To

tie down the awning to the ground would have prevented to change the position if

the sun has moved without bigger efforts and in addition the cabin is put

flexible onto the frame of the truck. As a result entering of leaving the cabin

would have pulled out the tent pegs or stressed the tie down ropes or the awning

itself.

Meanwhile I was able to grind off the

logos of the container. The top and the left side are painted with ant-rust

paint, the edges were sealed and the bigger scratches treated with knifing putty.

Besucher/Visitors

Besucher/Visitors